A Medieval Ink Recipe

27 Jan 2021|

- Research

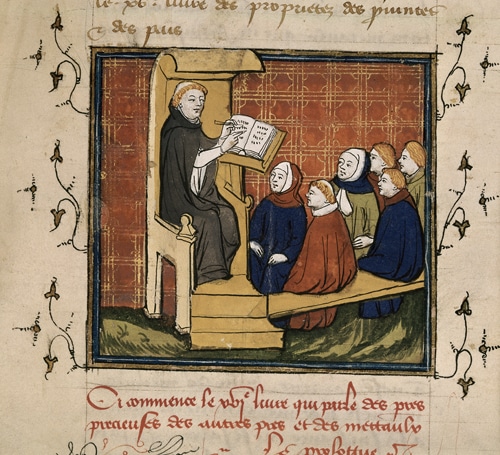

Medieval scribes didn’t only copy words onto parchment and paper. Many of them also made the ink that they worked with. As part of my research on the production of medieval books, I’ve recently been reading a lot of ink recipes. These short texts describe how both professional scribes and curious amateurs could make their own ink. They provide a window onto the history of a substance that is all around us, but that we rarely pay much attention to in its own right.

One such recipe survives in Cambridge, University Library, MS E.e.i.15, a small notebook that dates from around the start of the fifteenth century:

‘To make gode blak yngk as ony ys in Ynglond. Take an vnce [ounce] of gallys, an vnce of gume, and an vnce of grene coperose, brose [crush] all thyse togeder almost to pouder and put hit in a pott … than put therto a pynte of rayne water or of stondyng water that rynneth nott, than stere [stir] hyt euery daye and within .iii. dayis ye schall have gode yng’

The ink described here is usually known as iron gall ink. This type of ink was widely used until the introduction of synthetic alternatives in the nineteenth century. Oak galls—‘gallys’—are the result of a remarkable chemical reaction. They form when the female gall wasp punctures twigs or leaf buds on young trees to lay her eggs. The hatched larvae feed on the exposed part of the tree. They secrete an irritant as they do so that prompts the tree to create a growth around them. After the larva has developed into a wasp, it chews its way out of the gall. The flesh of oak galls are rich in tannins and gallic acid. They were collected, crushed and then either boiled in water, wine or vinegar, or slowly fermented in a warm place.

‘Coperose’ refers to iron sulphate, which was usually obtained as a by-product of the mining and processing of silver, copper, and tin. Iron gall ink is purple-black when it is first made but turns rusty brown over time due to the oxidisation of the iron particles.

‘Gum’, or ‘gum Arabic’ as it is also known in Middle English recipes, is perhaps the most intriguing ingredient in medieval ink—it was certainly the one I knew the least about. Gum Arabic is the exuded sap of two of the twenty-four species of the Acacia tree that are found in the Sahel in North Africa. In the Middle Ages, it was imported to Europe via ports in North Africa and the Levant. Its name therefore reflects its passage through the hands of Arab traders, rather than its point of origin.

It is one the world’s most enduringly useful multipurpose materials. It dissolves quickly in a small volume of water, where it forms a film around molecules of pigment, aroma, or flavour, that keeps them in suspension. It is safe to consume and is tasteless. Gum Arabic was vital to the expansion of Europe’s textile industries in the seventeenth and eighteenth centuries. European nations’ attempts to control its supply exerted a significant influence on the course of their colonial domination and exploitation of Africa. It is still vital to multiple industries. You might even have consumed some today. Gum Arabic, or E414 as it is also known, is often used in the production of soft drinks, sweets, ice cream, beer, wine, and many dairy products, as well as in cosmetics and toothpaste.

Late medieval ink recipes reveal the materials, techniques, and patience required before a scribe could put pen to page. They also provide a snapshot of the extensive late medieval trade networks that transported goods and materials, often over significant distances. And in the case of gum Arabic in particular, tracking the history of these materials is also to see some surprising connections between past and present.

Category: Research